Ceramics Development at ASU for High Pressure Applications

Kurt Leinenweber

An ongoing program in development of ceramics for high pressure applications exists at ASU. The ceramics are developed through collaboration with various companies, and discussions with William Petuskey, who is a Professor of Chemistry and studies ceramics.

Injection-Molded Octahedra

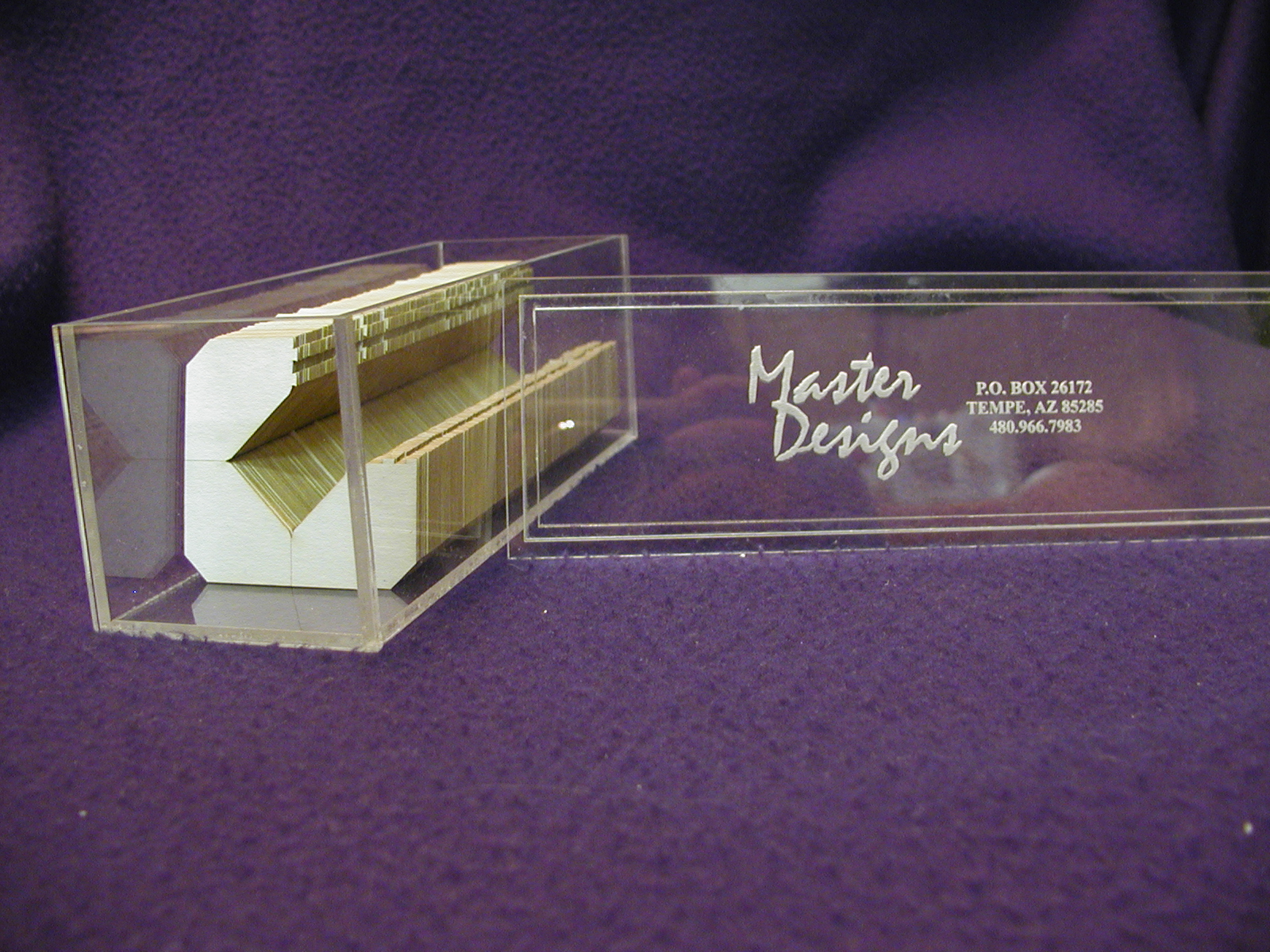

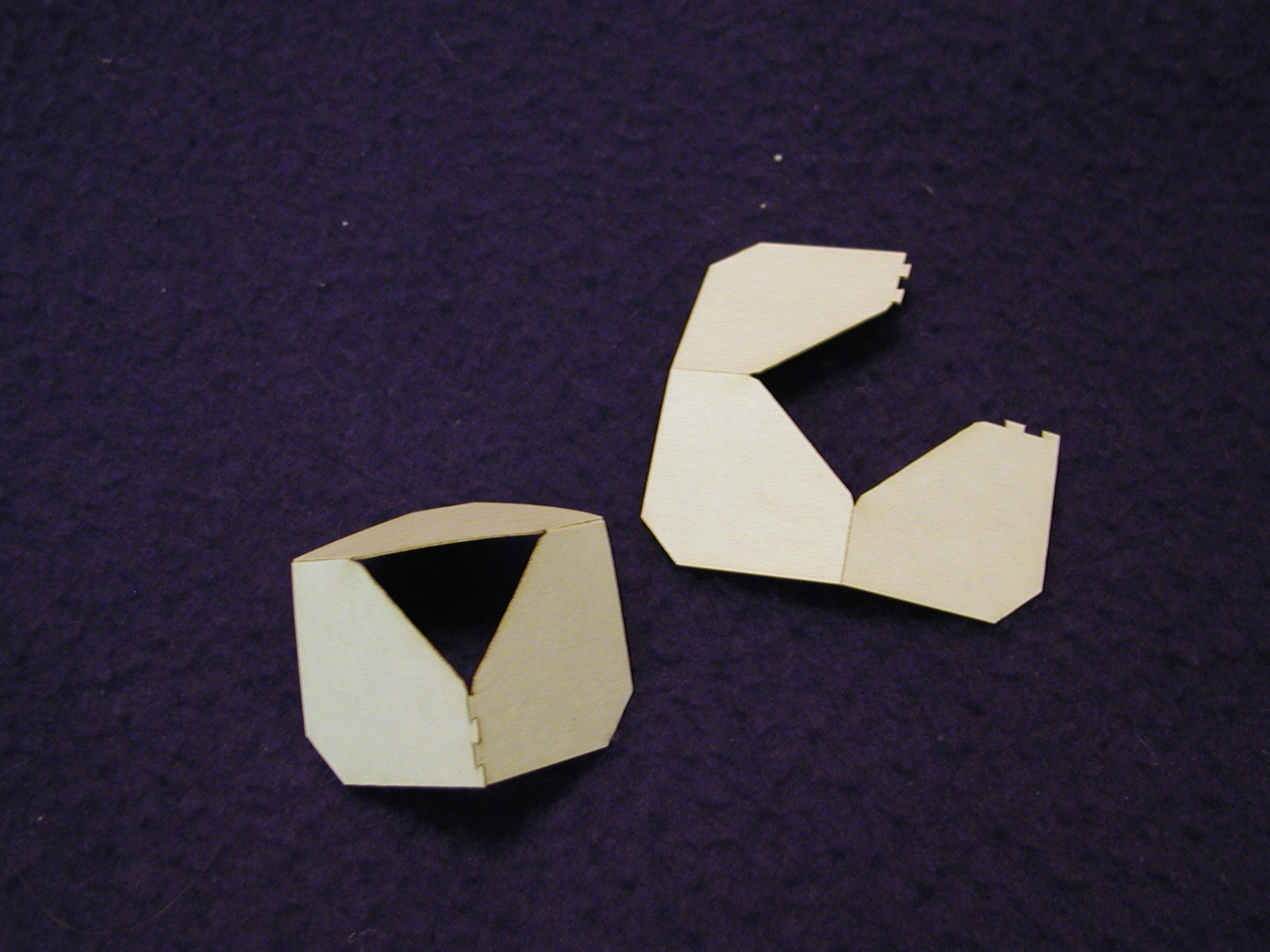

One development thrust is in injection-molding of ceramic parts. This is an inexpensive and highly reproducible technique; the octahedra shown in Figs.1 and 2, for example, can be made for about $5 apiece. Also, the shapes can be complex; octahedra can be made with grooves, holes, etc., and there is no cracking or frothing. The weights of the pieces are within 1% standard deviation. The drawbacks are that the technique is standard only for a limited range of compositions and porosities, and new formulas have to be developed for most high pressure applications. The startup costs are high because molds and ceramic mixtures have to be prepared. Finally, the number of ceramic parts used daily in high pressure research is small, and the variety of parts large, compared to the aspirations of most injection-molding companies (resulting in the large size of the minimum "startup batch" shown in Figure 1)..

Fig.1: Injection-molded octahedra (test batch).

Fig. 2: Injection-molded octahedra close-up.

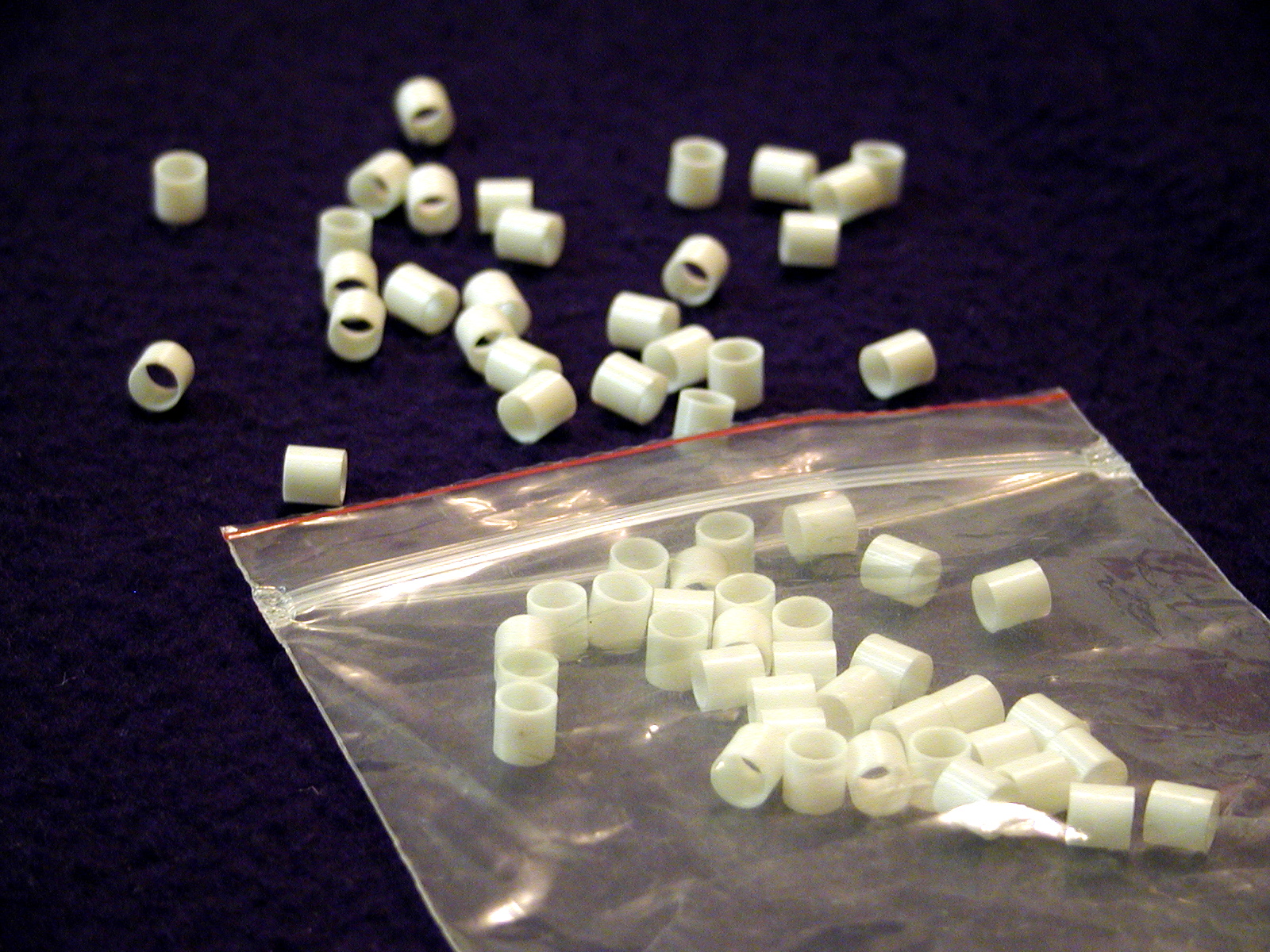

Injection-molded Zirconia

ASU uses injection-molded zirconia sleeves for thermal insulation, instead of machined sleeves. Zirconia is commonly used for thermal insulation in high-pressure applications, and is placed directly around the furnace. Injection molding of zirconia is a routine process, but so far all the companies fire the zirconia to near-theoretical density. High-pressure cells seem to work best with ceramics that are about 70 percent dense; this allows proper and uniform compaction of the entire assembly.

Ceramics testing

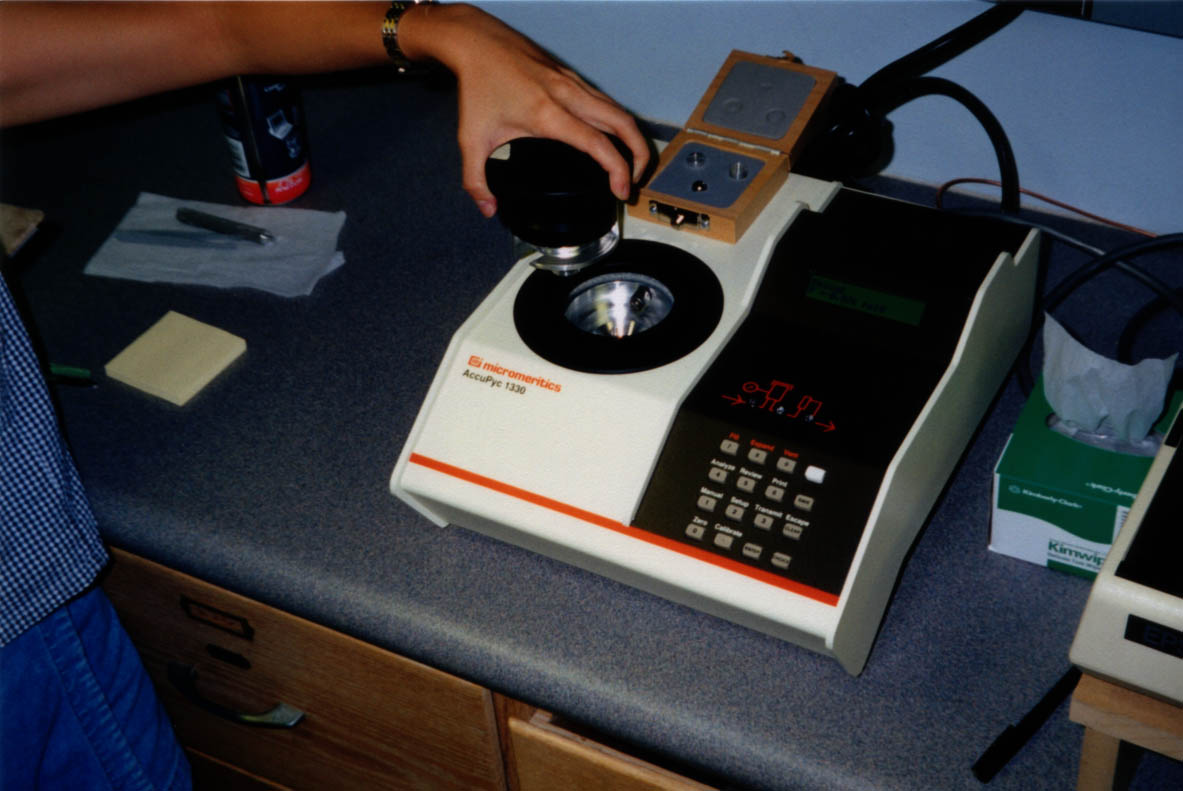

Besides testing ceramics under conditions of actual use in multianvil assemblies, other techniques may be used to examine ceramics and in some cases this can help to interpret the behavior of cell assembies, and identify possible sources of sample contamination. Tests that may readily be performed ex-situ both before and after a high-pressure run include density measurements, pycnometry to measure open porosity (Fig. 3), x-ray diffraction, optical microscopy, and electron probe microanalysis.

Fig. 3. Pycnometry

is used to measure the open porosity of ceramics.

Fig. 3. Pycnometry

is used to measure the open porosity of ceramics.

Such testing has been used extensively at ASU. Elements such as lithium and chromium have been found in precious metal tubing (left over from the extrusion process); transitions of ceramics to high pressure phases have been identified, and bad batches of ceramics and ceramics with poor reproducibility or low precision in density have been singled out using these techniques.