I. Designing and Developing Multianvil Cell Assemblies

The first step will be to design and develop cell assemblies. The expertise of the community will be pooled and principles of cell assembly design examined. Research into ceramics and metals will also be performed, to search for new ceramics that may find applications in multianvil cells.

The designs will include a series of truncation sizes for pressures from 0 to 27 GPa, a range of temperature capabilities from room temperature to the highest temperatures attainable (in excess of 2500 K), and both large-volume and low thermal gradient assemblies. Not all of these needs will be met by one assembly, so there will likely be several assemblies per truncation size. A separate group of assemblies will be developed using low-atomic number materials for experiments in the x-ray beamlines; the particular challenge here will be thermal insulation around the furnace, since most thermally insulating ceramics have high atomic numbers. Silicon carbide, which with recent ceramics technologies can be machined in the green state and fired to form the final product, is an example of a potential furnace material for this application.

The design phase will include thermal modeling, with various idea for cell assemblies being tested theoretically for thermal gradients. Procurement of ceramics will be undertaken, samples of these will be characterized and checked for composition, density, and porosty, which factor in to the high pressure behavior and the interaction with samples. Future shipments will be tested against these measurements, because the reproducibility of ceramics factors into the reproducibility of pressure calibrations in multi-anvil experiments.

Preparation of prototypes will be undertaken at the machining facility, and they will be available to Consortium members for testing.

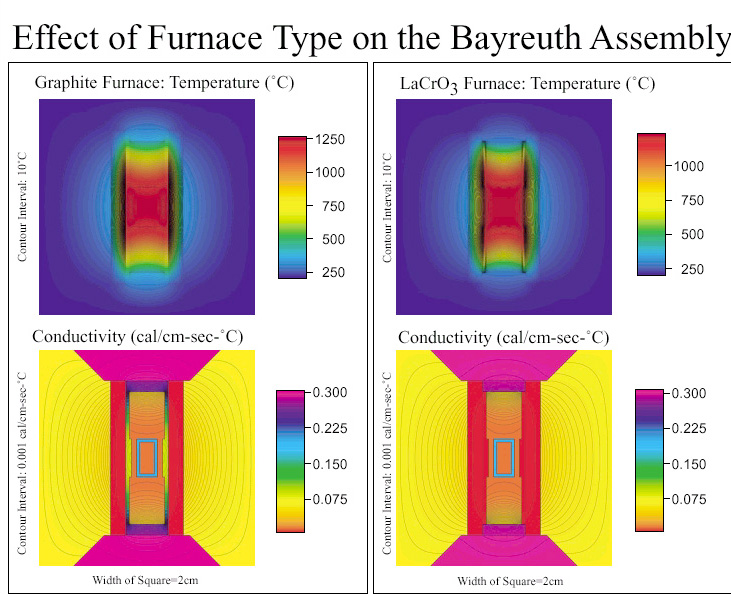

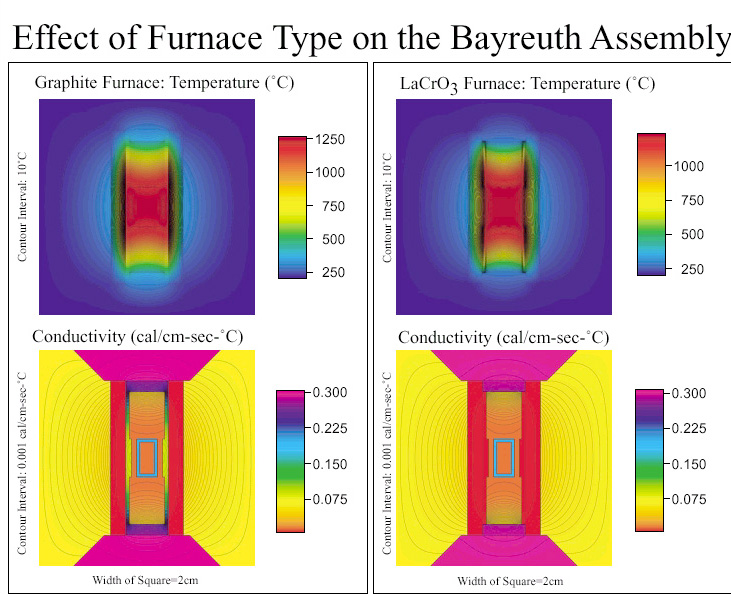

Thermal Modeling

Fig. Sample thermal model for the 8 mm Bayreuth assembly, showing that the thermal gradient within the sample depends on whether graphite or lanthanum chromite heaters are used. The thermal gradient for the Bayreuth lanthanum chromite heater was one of the lowest calculated in this study, by Hernlund et al. (2000).

Ceramics Testing

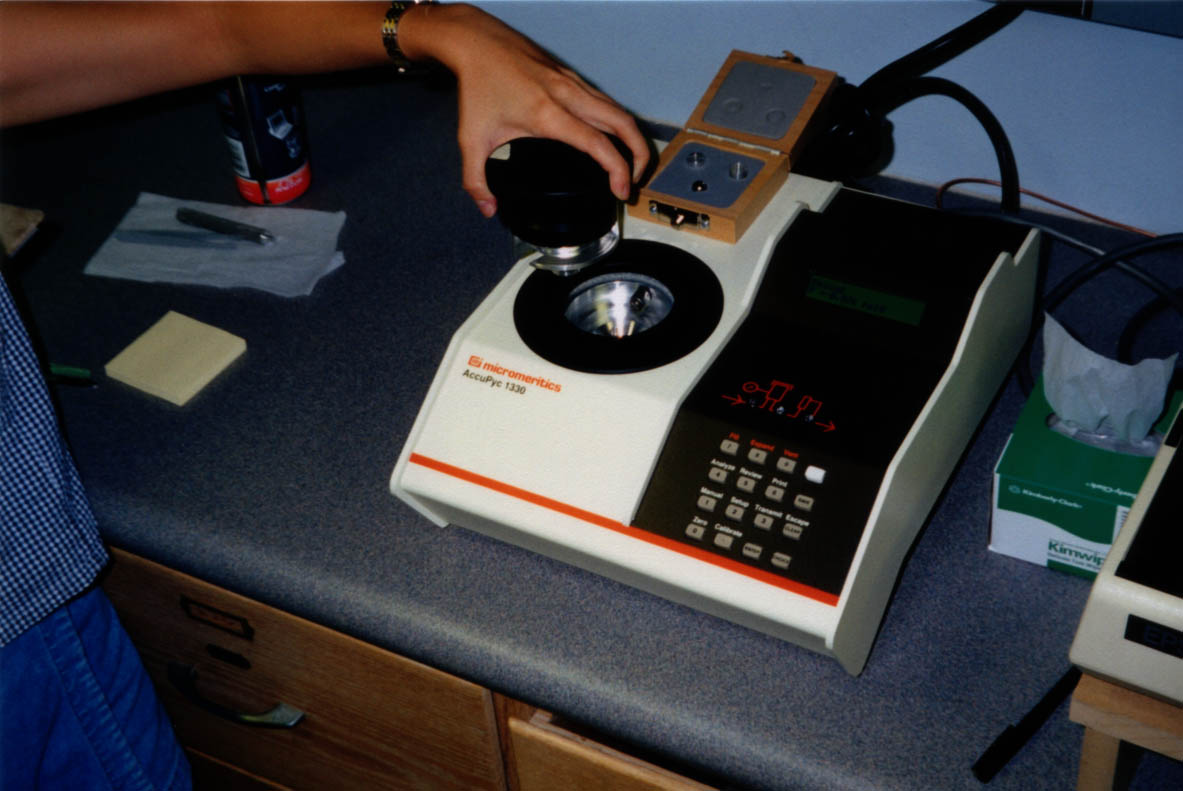

Besides testing ceramics under conditions of actual use in multianvil assemblies, other techniques may be used to examine ceramics and in some cases this can help to interpret the behavior of cell assembies, and identify possible sources of sample contamination. Tests that may readily be performed ex-situ both before and after a high-pressure run include density measurements, pycnometry to measure open porosity (Figure), x-ray diffraction, optical microscopy, secondary ion mass spectrometry (SIMS), and electron probe microanalysis.

Fig. Pycnometry is

used to measure the open porosity of ceramics.

Fig. Pycnometry is

used to measure the open porosity of ceramics.

Elements such as lithium and chromium have been found in precious metal tubing (left over from the extrusion process); transitions of ceramics to high pressure phases have been identified, and bad batches of ceramics and ceramics with poor reproducibility or low precision in density have been singled out using these techniques.