II. Testing and Interlaboratory Calibration of Cell Assemblies

Interlaboratory calibration comparisons have been made from time to time (cf. first two figures below), and the results have helped to troubleshoot various labs and produce better results. The difference with this new project is that direct comparisons of forces will be made between laboratories, using devices such as the "strain cube" (below) and other force calibration devices; and the calibrations will be pinned to detailed force/pressure/temperature relations gathered at the APS beamline. Measurements of thermal gradients for comparison with heat-flow calculations will also be made at the beamline, using the variation of unit cell parameters (thermal expansion or contraction) away from the thermocouple..

Subtle effects such as the pressure-buffering by phase transformations in zirconia sleeves during heating are expected to become evident in such detailed data. This, along with the knowledge of the pressure behavior during heating all the way from room temperature to high temperatures, will make the results from multianvil recovery experiments more precise.

Examples of calibration comparisons (current data)

Fig. Calibration comparisons of some 14/8 assemblies (Righter and Leinenweber).

Calibration comparisons of castable assemblies (Righter and Leinenweber).

Towards better interlaboratory comparisons.

Comparisons are most useful when the underlying causes for differences between laboratories can be found.

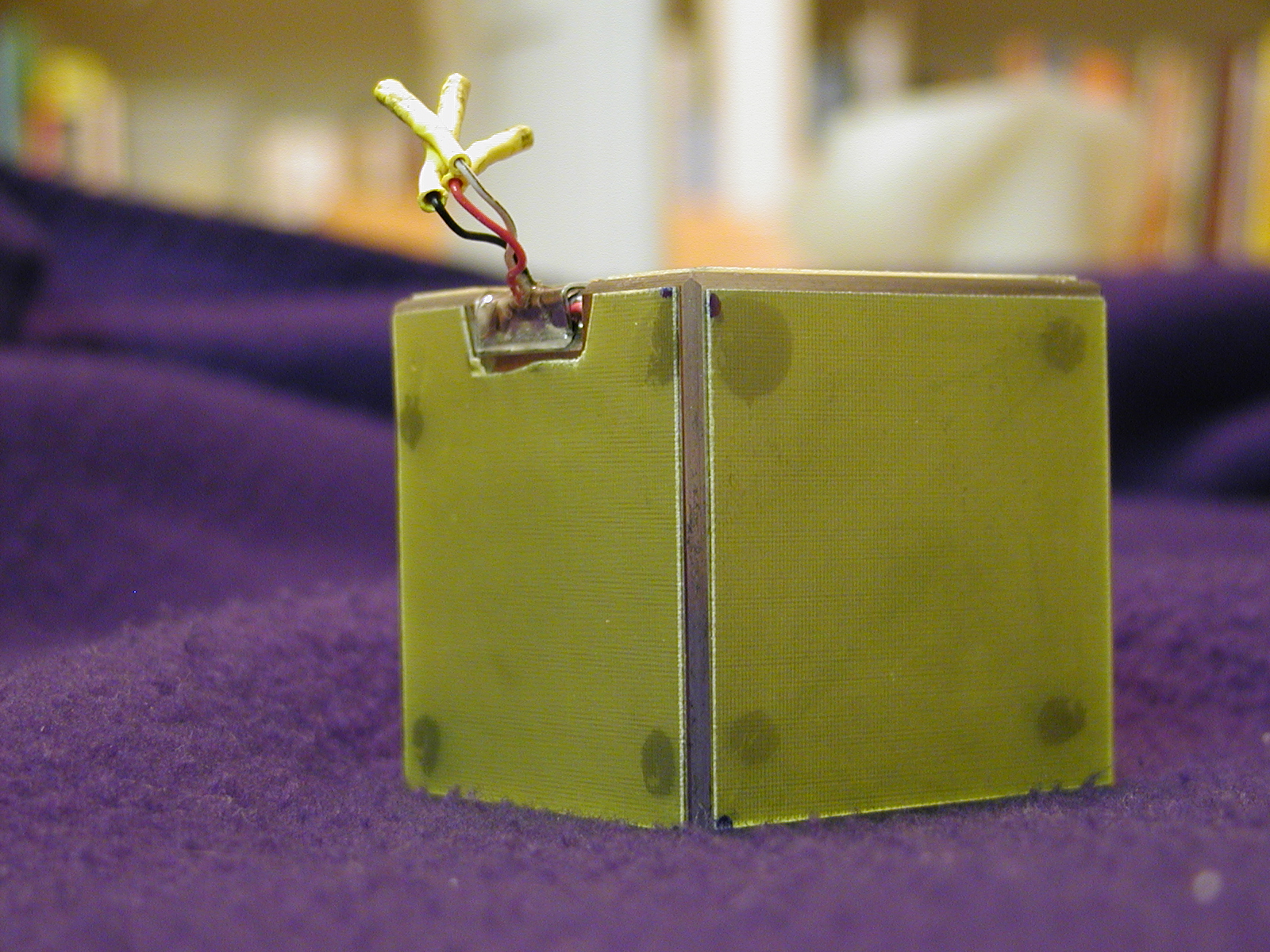

Recenlty, a "strain cube" has been developed and used to compare rams at 3 locations: Arizona State University (Walker module), GeoCARS at Argonne's Advanced Photon Source (T-cup), and the University of Arizona (Walker module). Measurements such as these will form one piece of the interlaboratory comparison that will underlie the Cell Assembly Development effort.

Figure: Strain gauge mounted inside a bevel on the edge

of a steel cube, used to compare ram efficiencies between different mulatianvils.

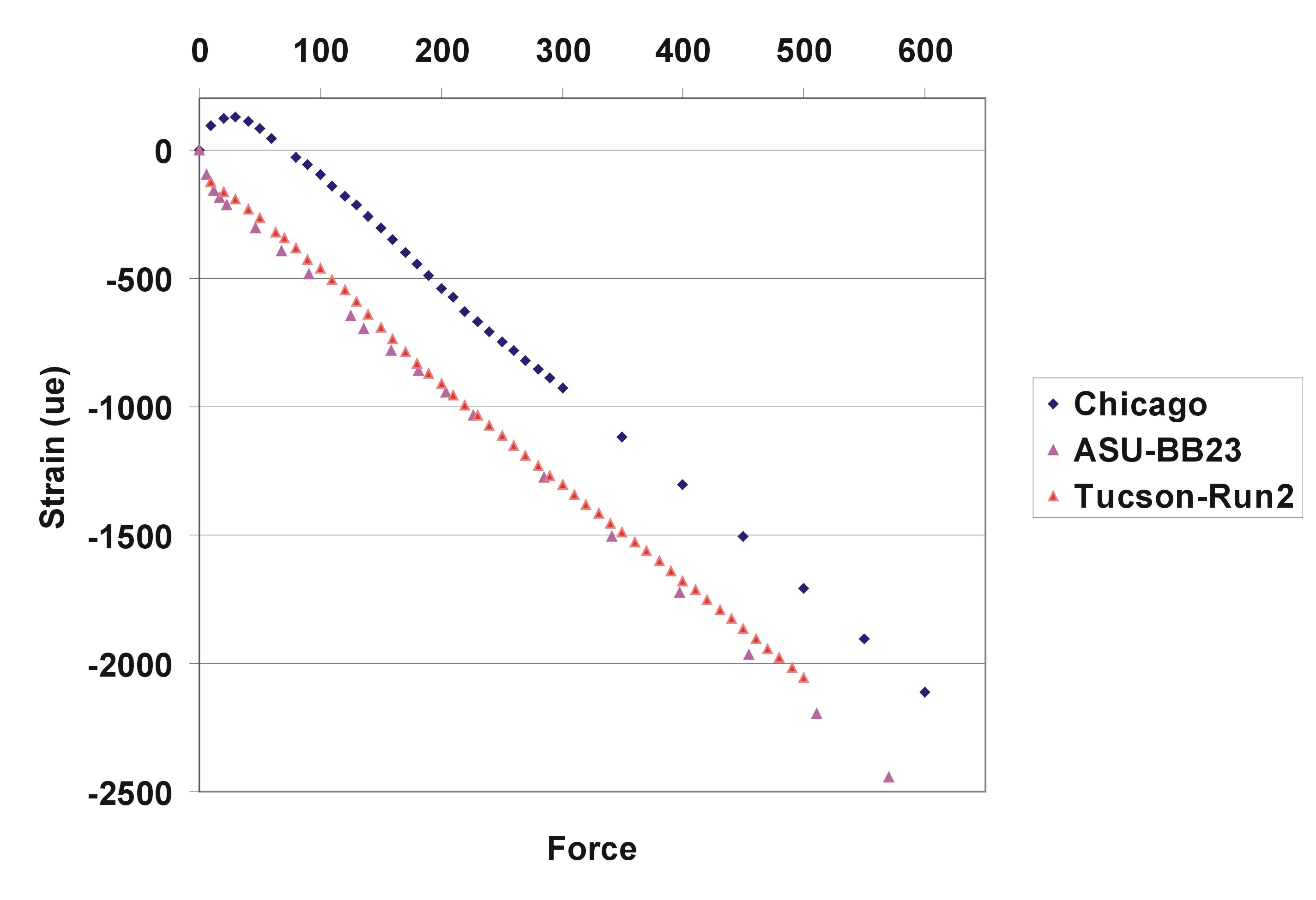

Fig. Strain comparison between the T-Cup at Chicago APS, the "Big Blue" Walker-style multianvil press at Arizona State University (ASU BB23), and the Walker-style multianvil press at University of Arizona in Tucson (Tucson - Run 2). All 3 presses have a ram diameter of 17 inches. The initial behavior reflects only the alignment of the guideblocks relative to the strain cube; however, the final slopes represent the real efficiency, and show that all 3 modules have very similar efficiencies despite their different designs.